Careful step-by-step pressing, combined with trimming, clipping, and grading, eliminates excess fabric thickness and creates a crisp, custom finish. The goal is to produce seams, darts, edges,and corners that are smooth flat, and thin.

This cannot be achieved if all pressing is left until last or correct trimming, clipping, and grading methods are not used.

Correct pressing opens and flattens seams, hems, and enclosed edges without leaving imprints on the right side of the garment. It is also sets the shape in curved seams, darts and shrinks out fullness in sleeve caps and hems. The original texture colour, and finish of the fabric are retained when pressing is done correctly.

Tips for Pressing

Test iron setting and effects of steam on a sample seam and dart sewn in fabric scraps.

Press, using lower-pause-lift motion. Do not slide iron from place to place.

Do most pressing on wrong side of fabric. Use correct press cloth when pressing from the right side. The press cloth protects fabric from overpressing and from changes in fabric surface, hand and appearance.

Do Not press over pins or basting unless the basting is stitched with silk thread.

Keep seamline perfectly straight when pressing straight seams, so seams and darts on shaped pressing equipment to prevent distorted or stitched lines.

Allow pressed areas to cool before moving. if fabric must be moved, lift and support it with both hands to prevent the fabric from stretching out of shape.

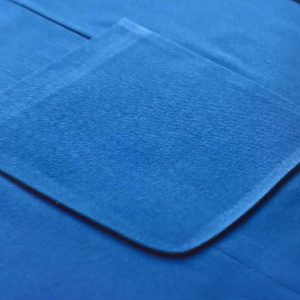

Perfectly Pressed

Perfectly Pressed seams, darts, and edges are thin, smooth, and pucker free with no edge imprints on the right side. Fabric texture does not change when pressed correctly.

Overpressed

Overpressed seams, darts, and edges imprint to the outside. Fabric is shiny and flattened from too much heat or pressure. Overpressing with too much moisture may shrink the seamline and cause ripples.

Underpressed

Underpressed edges are rounded, and seams and darts have pronounced wells, or indentations.